Distillation column components manufacturer

Specializing in the Manufacuring & Exporting Distillation Column Components

At Kuber Auto Pressing, we take pride in being a trusted distillation column components manufacturer. With our expertise in precision engineering and commitment to delivering excellence, we cater to the needs of various industries, including chemical, pharmaceutical, oil and gas, and more.

Kuber Auto Pressing has a reputation for excellence. We offer a wide range of distillation column components that meet the highest standards in the industry. Our equipment’s commitment to quality is evident in every product we manufacture. We use only the best materials and employ skilled technicians who ensure that each component meets exacting standards.

If you’re looking for a distillation column components manufacturer that you can trust, look no further than Kuber Auto Pressings. With our extensive experience in the industry and dedication to quality, we are sure to provide you with the perfect solution for your business needs.

Why choose Kuber Auto Pressing as Distillation Column Components Manufacturer?

Quality Distillation Column Components

We utilize state-of-the-art manufacturing techniques and employ stringent quality control measures to ensure that our products meet the highest industry standards.

Customized Solutions

Our team of experienced engineers works closely with you to understand your needs and deliver components that optimize your distillation operations.

Reliability and Timely Delivery

We are committed to delivering top-quality distillation column components within the agreed timelines. Our efficient logistics network ensures that your components reach you on time, minimizing downtime and maximizing productivity.

Customer Satisfaction

Customer satisfaction is at the core of our business philosophy. We believe in establishing long-term partnerships with our clients by providing exceptional products and reliable services.

High Quality Products For All Your Industrial Needs!

SHEET METAL COMPONENTS

DEEP DRAW COMPONENTS

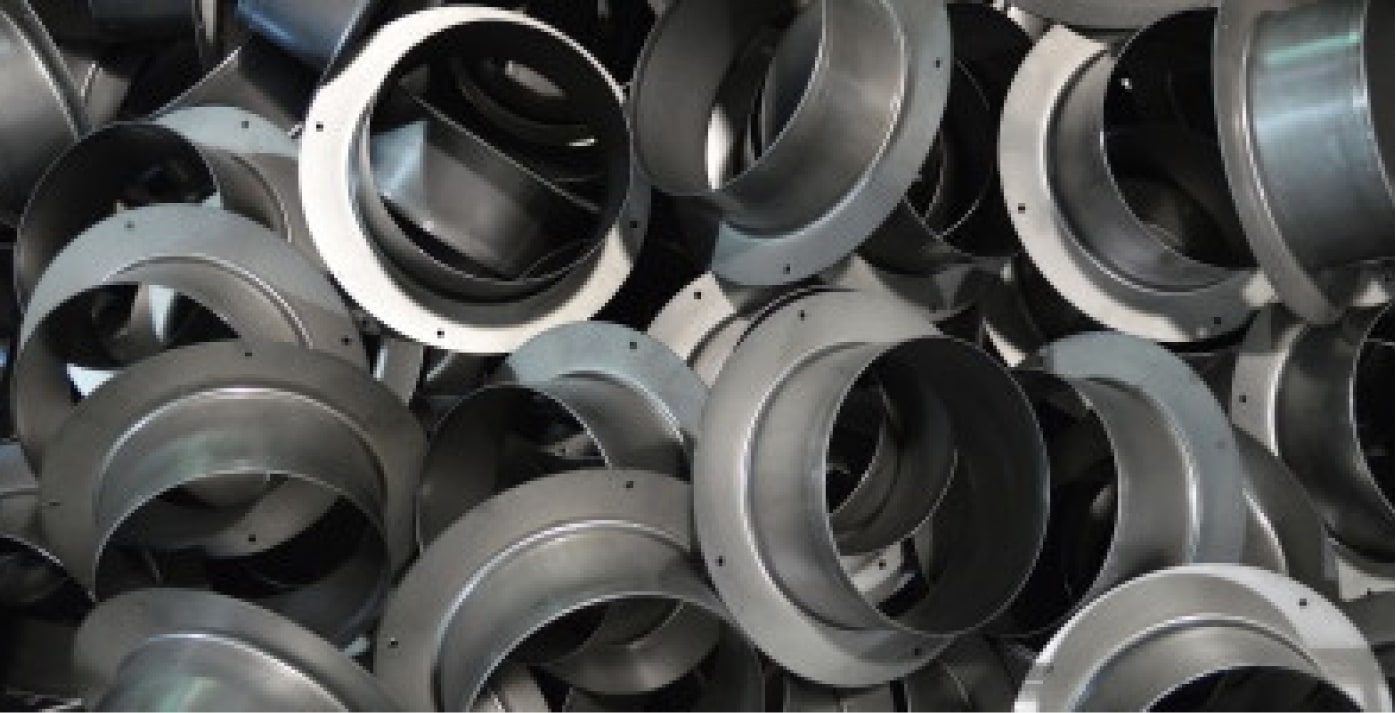

VALVE COMPONENTS

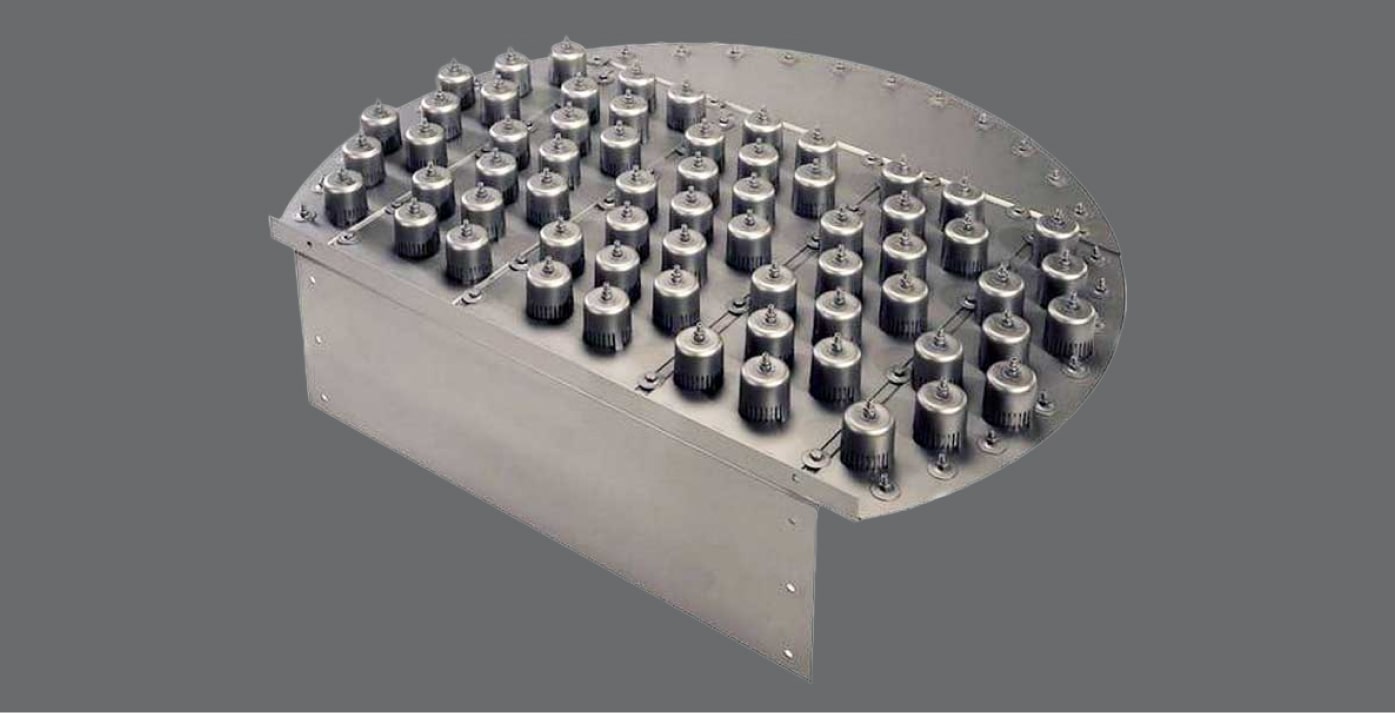

BUBBLE CAPS

BUBBLE CAP RAISERS

CNC MACHINED COMPONENTS

PIPE FLARING AND SWAGING

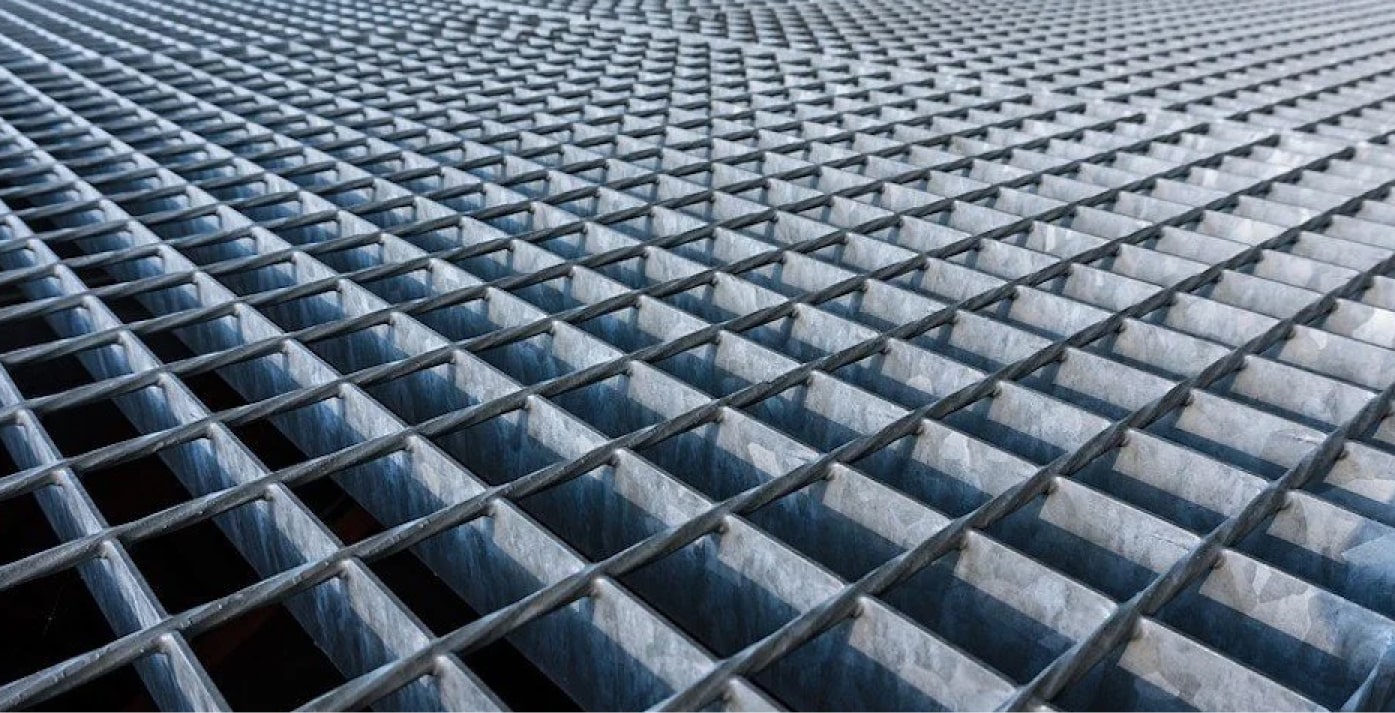

MS GRATINGS

- Numbers Speak For Themselves.

Building Relationships With Clients All Over The World!

Projects we Design & Completed in 2020

Qualified Employees And Workers With Us

Satisfied Clients We Have Served Globally

Years Of Experience In The Construction Industry

Request A Quote

We will get back to you within 24 hours, or call us everyday, 10:00 AM - 07:00 PM

Dedication In Bringing You The Products Of Highest Quality!

Since 2004 KUBER AUTO PRESSING Helping Clients.

We are here to provide our customers with the new way to take advantage of the highest quality, service & value found in the Steel distribution industry.

Certified Company

Our Experience

FAQ

We manufacture a wide range of distillation column components, including structured packing, random packing, sieve trays, valve trays, bubble cap trays, distributors, liquid collectors, and other internals necessary for efficient separation processes. Know more