Pipe Flaring and Pipe Swaging Manufacturer

Can't Find What You're Looking For?

Get A Quote

Download

Kuber Auto Pressing is a renowned provider of pipe flaring and pipe swaging services. With our expertise and advanced machinery, they offer high-quality solutions for shaping and connecting pipes in various industries, including automotive.

Pipe flaring is a process employed to expand the end of a pipe, creating a larger diameter opening. This technique is crucial for ensuring secure and leak-free connections between pipes. Kuber Auto Pressing excels in pipe flaring, utilizing precision tools and skilled operators to achieve consistent and accurate results. By carefully expanding the pipe end, they create a wider surface area, which enhances the sealing capacity and strengthens the joint. This meticulous approach guarantees reliable and durable pipe connections, meeting the highest industry standards.

Pipe swaging, another specialized service offered by Kuber Auto Pressing, involves reducing the diameter of a pipe while maintaining a consistent thickness. This technique is commonly utilized when transitioning between pipes of different sizes or when fitting pipes into tight spaces.

Kuber Auto Pressing state-of-the-art machinery and skilled technicians ensure precise and uniform pipe swaging. By carefully controlling the reduction process, they create seamless transitions, enabling efficient fluid flow and minimizing pressure losses. The tight and secure fit achieved through our swaging services enhances the overall performance and reliability of the piping system.

Kuber Auto Pressing pipe flaring and pipe swaging services are backed by our commitment to quality and customer satisfaction. We adhere to strict quality control measures throughout the entire process, ensuring that each flared or swaged pipe meets the required specifications. With our expertise and attention to detail, they guarantee optimal functionality, compatibility, and longevity of the pipes in automotive and other industries.

What is Pipe Flaring and Pipe Swaging?

Pipe Flaring

Pipe flaring involves expanding the end of a pipe to create a larger diameter opening. This is typically achieved by using a specialized tool that gradually widens the pipe’s end. The process results in a flared shape, with the outer diameter of the flared section being larger than the original pipe diameter.

Flaring is commonly employed in applications where a secure and leak-proof connection is required between pipes or fittings. The flared end provides a wider surface area for attaching other components, such as fittings, valves, or connectors. It enhances the sealing capability and improves the overall strength of the joint. Pipe flaring is often utilized in industries such as automotive, plumbing, HVAC (heating, ventilation, and air conditioning), and hydraulic systems.

Pipe Swaging

Pipe swaging, also known as tube swaging, is the process of reducing the diameter of a pipe while maintaining its consistent thickness. Swaging is typically performed on the end of a pipe to achieve a tapered or reduced diameter section.

Swaging serves multiple purposes, including transitioning between pipes of different sizes, fitting pipes into tight spaces, or creating a specific shape for aesthetic or functional purposes. It allows for seamless integration between pipes with varying diameters, ensuring smooth fluid flow and minimizing pressure losses. Pipe swaging is commonly used in industries such as aerospace, automotive, oil and gas, and construction.

Both pipe flaring and pipe swaging techniques require specialized tools and equipment, as well as skilled operators who understand the properties of the materials being worked on. These processes play a crucial role in creating secure connections, optimizing fluid flow, and ensuring the efficient operation of various systems that rely on pipes and tubing.

Key Features of Pipe Flaring and Pipe Swaging Techniques

Secure Connections

Leak Resistance

Strength and Durability

Flared and swaged connections offer increased strength and durability. The wider surface area of a flared joint distributes forces more evenly, reducing stress concentration points and enhancing the overall strength of the connection. Swaging ensures a tight and secure fit between pipes, minimizing the risk of separation or failure under pressure or mechanical stress.

Seamless Transitions

Versatility

Enhanced Performance

Things to Consider When Selecting a Pipe Flaring and Pipe Swaging service provider

When choosing a Pipe Flaring and Pipe Swaging provider, it is essential to consider the following factors:

1. Quality and Reliability

Select a manufacturer known for producing bubble caps of exceptional quality, ensuring durability and resistance to corrosion, which leads to reliable and long-lasting performance.

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

APPLICATION INDUSTRY - Pipe Flaring and Pipe Swaging Manufacturer

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

Motors

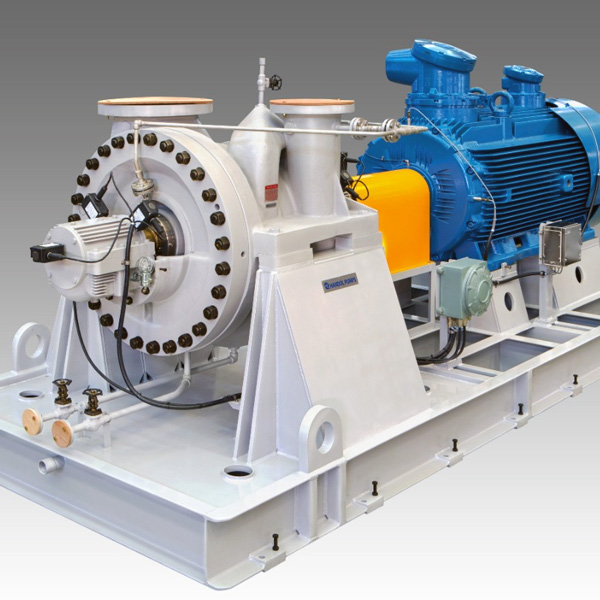

Pumps

Valves

Learn more about our Product Mild Steel Gratings Manufacturer

Get In Touch

FAQ

Pipe flaring and pipe swaging provide several advantages over other connection methods. They offer secure and reliable connections, enhanced sealing capabilities, and improved strength compared to methods like threaded connections or adhesive bonding. These techniques also allow for efficient fluid flow, minimizing pressure losses and turbulence within the piping system. Contact Us