Air Dryer

Can’t Find What You’re Looking For?

Get A Quote

Download

AIR DRYER

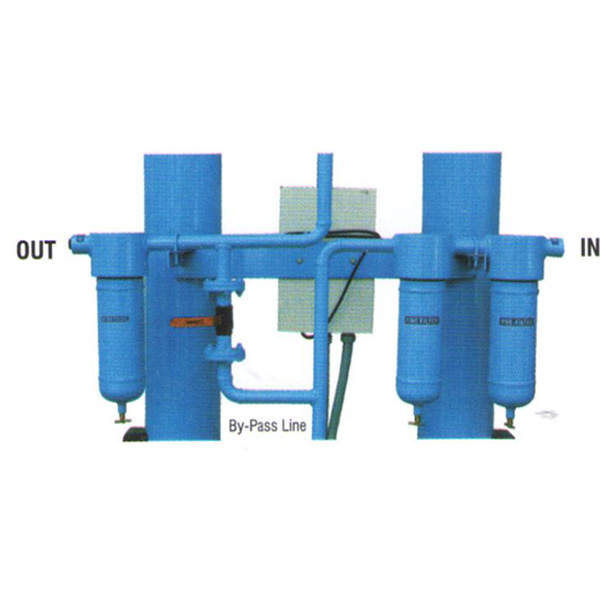

Desiccant Air Dryer (Heatless Type)

Condensate moisture along with oil and dust particles for downstream application is a major problem. The only way to remove these unwanted contaminants (Heatless) dryer is a complete purification package, it includes filtration plus drying.

- Filtration: Before drying, wet air enters Pre Filter in series. i,e first air enters into pre filter of sintered bronze element and removes all major dust particles along with big droplets of moisture and oil. The air flow direction in this PF is from out to In. This will help to reduce early chocking from major particles. In Second stage fitter (MF) micro filter which is made up of micro glass fiber removes mist form of moisture and oil along with small dust particles up to 0.2p. This type of filter enhances the life of solenoid valves and increases life of desiccant in the drying tower.

- Drying: After pre filtration only vapour content of moisture which is major contribution in the air will enter into desiccant towers. Both towers are totally filled up with desiccant and type of desiccant depends upon desired dew point required for application. Solenoid valves are controlled by the control panel (Timer based).At the initial stage both towers will remain open for 15 seconds to bring both towers in pressurized mode. After pressurized mode one tower will be in drying mode to adsorb vaporized moisture and second tower will be in regeneration mode. The total cycle time will be of 10 min. To remove minute particles after dryer, dust filter is adopted at the outlet of dryer.The quality of air at the std. dryer

Standard Models At 7Kg/Cm2

| Sr. No. | Capacity | End Connection | Overall Dimensions in mm Approx. |

|---|---|---|---|

| 1. | 10 CFM | 1/2" BSPT (F) | 750 x 400 x 1100 |

| 2. | 15 CFM | 1/2" BSPT (F) | 850 x 400 x 1500 |

| 3. | 20 CFM | 1/2" BSPT (F) | 850 x 400 x 1750 |

| 4. | 25 CFM | 1/2" BSPT (F) | 850 x 400 x 1800 |

| 5. | 30 CFM | 1/2" BSPT (F) | 850 x 500 x 1850 |

| 6. | 40 CFM | 3/4" BSPT (F) | 900 x 500 x 1900 |

| 7. | 60 CFM | 3/4" BSPT (F) | 1000 x 500 x 1950 |

| 8. | 80 CFM | 1" BSPT (F) | 1150 x 600 x 2000 |

| 9. | 100 CFM | 1" BSPT (F) | 1200 x 600 x 2100 |

| 10. | 120 CFM | 1" BSPT (F) | 1250 x 600 x 2100 |

| 11. | 150 CFM | 1 1/2" BSPT (F) | 1250 x 650 x 2100 |

| 12. | 200 CFM | 1 1/2" FLGD ASA 150# | 1250 x 650 x 2100 |

| 13. | 250 CFM | 1 1/2" FLGD ASA 150# | 1250 x 700 x 2150 |

| 14. | 300 CFM | 1 1/2" FLGD ASA 150# | 1400 x 800 x 2150 |

| 15. | 400 CFM | 2" FLGD ASA 150# | 1600 x 800 x 2150 |

| 16. | 500 CFM | 2" FLGD ASA 150# | 1800 x 1000 x 2200 |

| 17. | 800 CFM | 3" FLGD ASA 150# | 2000 x 1050 x 2200 |

| 18. | 1000 CFM | 4" FLGD ASA 150# | 2200 x 1200 x 2200 |

| 19. | 1500 CFM | 4" FLGD ASA 150# | 2400 x 1500 x 2250 |

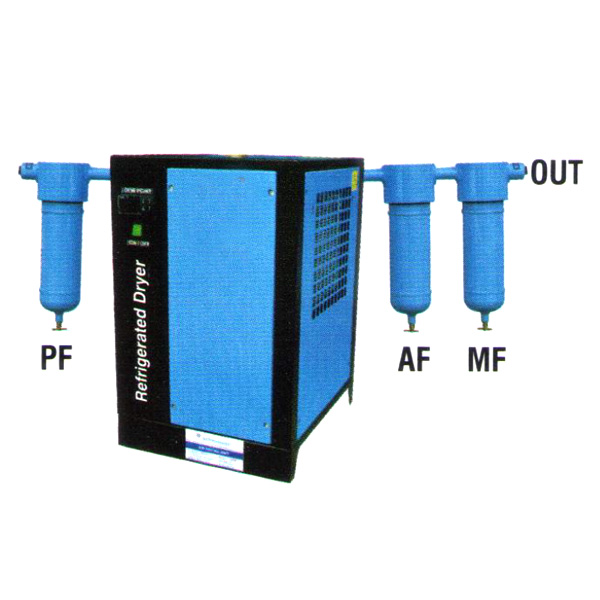

Refrigerated Air Dryer

he wet compressed air enters in to compact three in one heat exchanger (Economizer,Evaporator & Moisture Separator) for pre cooling and passes through moisture separator and separates condensate and will be discharged by auto drain valve. The cooled and dried compressed air will return through heat exchanger and passes through outlet. Key Features

- Compact Three-in-One heat exchanger.

- Aluminium plate finned cross flow heat exchanger.

- Reliable refrigerated compressor having eco-friendly refrigerant, low noise level/less power consumption

- Total modular canopy design, interchangeability, easy fitment of all components and the data from microcontroller ensures preventive Maintenance and easy serviceability

Technical Specification

| Airflow | Max. Op. Pressure | Power Supply | Version | Line Size | End Conn. | ||||

|---|---|---|---|---|---|---|---|---|---|

| m3/min | cfm | Kg/cm2 | psi | V/Ph/Hz | L | W | H | ||

| 0.57 | 20 | 12 | 171 | 230/1/50 | Air Cooled | 1/2" BSPT (F) | 480 | 400 | 625 |

| 1.13 | 40 | 12 | 171 | 230/1/50 | Air Cooled | 3/4" BSPT (F) | 480 | 400 | 625 |

| 1.7 | 60 | 12 | 171 | 230/1/50 | Air Cooled | %" BSPT (F) | 480 | 400 | 625 |

| 2.27 | 80 | 12 | 171 | 230/1/50 | Air Cooled | 1" BSPT (F) | 680 | 560 | 850 |

| 2.83 | 100 | 12 | 171 | 230/1/50 | Air Cooled | 1" BSPT (F) | 680 | 560 | 850 |

| 3.54 | 125 | 12 | 171 | 230/1/50 | Air Cooled | 1'/2" BSPT (F) | 680 | 560 | 850 |

| 4.25 | 150 | 12 | 171 | 230/1/50 | Air Cooled | 11/2" BSPT (F) | 680 | 560 | 850 |

| 5.66 | 200 | 12 | 171 | 230/1/50 | Air Cooled | 1 A" BSPT (F) | 750 | 650 | 1000 |

| 7.08 | 250 | 12 | 171 | 230/1/50 | Air Cooled | 1%2" BSPT (F) | 750 | 650 | 1000 |

| 8.49 | 300 | 12 | 171 | 415/3/50 | Air Cooled | 2" FLGD ASA 1504 | 950 | 850 | 1250 |

| 9.91 | 350 | 12 | 171 | 415/3/50 | Air Cooled | 2" FLGD ASA 1504 | 950 | 850 | 1250 |

| 12.74 | 450 | 12 | 1250 | 415/3/50 | Air Cooled | 2" FLGD ASA 1504 | 950 | 850 | 1250 |

| 15.57 | 550 | 12 | 171 | 415/3/50 | Air Cooled | 2 "A" FLGD ASA 1504 | 1000 | 900 | 1400 |

| 18.41 | 650 | 12 | 171 | 415/3/50 | Air Cooled | 2 /2" FLGD ASA 1504 | 1000 | 900 | 1400 |

| 21.24 | 750 | 12 | 171 | 415/3/50 | Air Cooled | 2 /2" FLGD ASA 1504 | 1000 | 900 | 1400 |

| 25.48 | 900 | 12 | 171 | 415/3/50 | Air Cooled | 3" FLGD ASA 1504 | 1250 | 1000 | 1550 |

| 28.32 | 1000 | 12 | 171 | 415/3/50 | Air Cooled | 3" FLGD ASA 1504 | 1250 | 1000 | 1550 |

| 31.15 | 1100 | 12 | 171 | 415/3/50 | Air Cooled | 3" FLGD ASA 1504 | 1250 | 1000 | 1550 |

Other Manufacturing Range

Coalescing Filters

Filter elements

Moisture Separator

After Cooler

Pressure Vessels (Air Receiver)

Duplex Filter

APPLICATION INDUSTRY

Powder Coating /Spray Painting

Pharmaceutical Industries

Automobile Industries

Engineering Industries

Textile

Dairy Industries

Plastic Industries

Sugar Industries

Power Sector

Hospitals

Chemical Industries

Breweries Industries