Deep Draw Components Manufacturer

Can’t Find What You’re Looking For?

Get A Quote

Download

Kuber Auto Pressing is a leading manufacturer of deep draw components, specializing in the production of high-quality and precision-engineered parts for various industries. Deep draw components are widely used in automotive, aerospace, electronics, and other sectors where complex shapes and tight tolerances are required.

Kuber Auto Pressing utilizes advanced deep drawing techniques and state-of-the-art machinery to manufacture deep draw components that meet industry standards and customer specifications. The company’s expertise in deep drawing allows them to create intricate and seamless components from various materials, including stainless steel, aluminum, brass, and copper.

Deep draw components are produced by Kuber Auto Pressing using a specialized process that involves drawing a flat sheet of metal into a three-dimensional shape through a series of forming operations. This process enables the creation of components with high precision and consistency, ensuring optimal performance and fit.

Kuber Auto Pressing offers a diverse range of deep draw components, including but not limited to cups, cans, enclosures, shells, and cylinders. These components are used in applications such as fuel systems, electrical connectors, sensor housings, and automotive parts. Kuber Auto Pressing works closely with customers to understand their specific requirements and provide customized solutions tailored to their needs.

Quality is of utmost importance to Kuber Auto Pressing, and they have stringent quality control measures in place throughout the manufacturing process. They conduct thorough inspections and testing to ensure that the deep draw components meet or exceed customer expectations in terms of dimensional accuracy, surface finish, strength, and functionality.

What are Deep Draw Components

Deep Drawing Process

Deep drawing is a metal forming process that involves the transformation of flat sheet metal into three-dimensional hollow shapes using a punch and die set. The process begins with a flat sheet of metal that is placed over the die, and a punch is used to push the metal into the die cavity, forming it into the desired shape. This process is repeated multiple times until the desired depth is achieved. The deep drawing process allows for the creation of complex shapes with excellent dimensional accuracy and uniform wall thickness.

Types of Deep Draw Components

Cups and Cylinders

Canisters and Containers

Enclosures and Housings

Automotive Components

Key Features of Deep Draw Components

Enhanced Strength

Cost-Effective

Improved Dimensional Accuracy

Versatile Material Selection

Things to Consider When Selecting a Deep Draw Components Manufacturer

1. Quality and Reliability

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

APPLICATION INDUSTRY

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

Motors

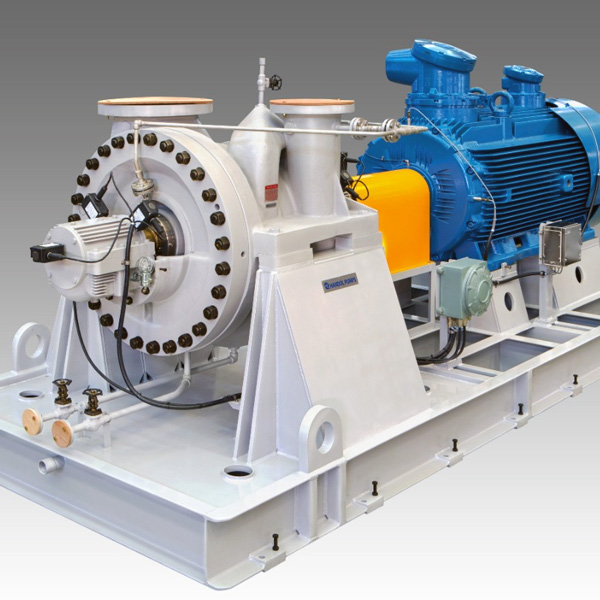

Pumps

Valves

Learn more about our Product Sheet Metal Components Manufacturer

Get In Touch

FAQ

Yes, deep draw components can be customized to meet specific requirements. Customization may involve adapting the shape, size, or material of the deep draw components to suit the intended application. Contact Us