Bubble Cap Manufacturer

Can't Find What You're Looking For?

Get A Quote

Download

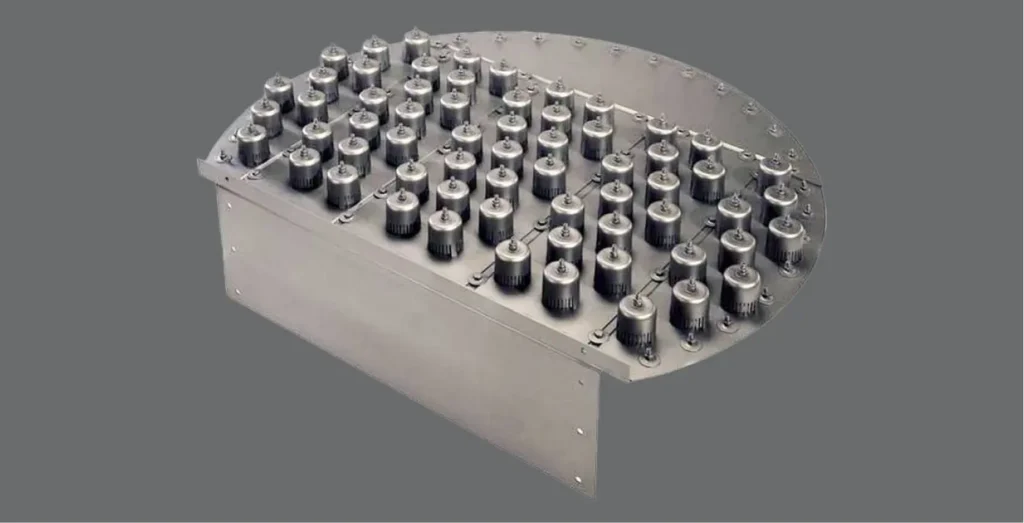

Kuber Auto Pressing is a renowned manufacturer of bubble caps, specializing in producing high-quality and efficient components for various industries. Bubble caps are essential elements used in distillation columns for the separation and purification of liquids in processes such as chemical production, oil refining, and pharmaceutical manufacturing.

Kuber Auto Pressing employs advanced manufacturing techniques and cutting-edge technology to produce bubble caps that meet industry standards and customer requirements. We prioritize precision engineering and attention to detail to ensure that each bubble cap is reliable and performs optimally in demanding environments.

Bubble caps manufactured by Kuber Auto Pressing are made from high-quality materials, such as stainless steel or other suitable alloys, which exhibit excellent corrosion resistance and durability. These materials are carefully chosen to withstand the aggressive chemical environments encountered in distillation processes, ensuring long-term performance and reliability.

Kuber Auto Pressing offers a diverse range of bubble caps with different designs and specifications to suit various distillation column configurations and applications. Our skilled engineers and technicians work closely with customers to understand their specific needs and provide tailored solutions that optimize column efficiency and productivity.

What are Bubble Caps?

A bubble cap is a mechanical device crucial to the success of distillation operations. It plays a vital role in separating liquid mixtures based on their different boiling points. By facilitating vapor-liquid contact, bubble caps improve the efficiency of distillation processes, enabling the extraction of desired components.

The design of a bubble cap consists of a cap-like structure with a vent or perforation located at the top, and a downcomer extending below it. As vapor ascends through the distillation column, it encounters the perforations in the bubble caps, creating gas pockets or bubbles. These bubbles promote the necessary vapor-liquid contact, leading to effective separation.

At Kuber Auto Pressing, we take pride in being a reliable bubble cap manufacturer, offering a wide range of high-quality bubble caps that cater to diverse distillation requirements. Our expertise, commitment to quality, and customer satisfaction drive us to deliver outstanding products and services.

Types of Bubble Caps

Cylindrical Bubble Caps

These bubble caps feature a cylindrical shape with a perforated top that allows vapor to pass through. The liquid flows down through the downcomer, and efficient separation occurs as the bubbles mix with the descending liquid.

Rising Stem Bubble Caps

Our rising stem bubble caps incorporate a central stem that rises or lifts when vapor enters the cap. This action creates an opening for vapor passage. As the stem rises, bubbles form, and vapor is distributed evenly across the liquid surface, facilitating separation.

Fixed Valve Bubble Caps

Our fixed valve bubble caps consist of a perforated cap with a fixed valve mechanism. The valve allows vapor to flow when pressure builds up, ensuring controlled vapor distribution and optimizing separation efficiency.

Swing Check Bubble Caps

Swing check bubble caps employ a swing check valve within the perforated cap. The valve swings open when vapor flows, enabling vapor passage. This design promotes superior vapor distribution and maximizes separation efficiency.

Stainless Steel Bubble Cap

Copper Alloy Bubble Cap

Alloy Steel bubble Cap

MS Bubble Cap

Key Features of Bubble Caps

- Wide range of turn down ratios without weeping.

- Dimensional Accuracy

- Precise Design

- Eco Friendly, Fine Finishing, Good Quality, Leak Proof

- Can handle corrosive liquids and suspended solids

- Robust contraction & Excellent durability

Things to Consider When Selecting a Bubble Cap Manufacturer

1. Quality and Reliability

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

Bubble Cap - Material Of Construction

| Material | Copper, Aluminium, Copper, Brass, Inconel, Titanium, Duplex Steel etc. |

| Sizes | Customized |

| Thickness | 1 mm to 10 mm |

| Usage/Application | Industrial |

| Features | Rust resistance property, Dimensional accuracy, Easy installation |

APPLICATION INDUSTRY - Bubble Cap Manufacturer

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

Motors

Pumps

Valves

Learn more about Bubble cap Raiser and fittings Manufacturer

Get In Touch

FAQ

Kuber auto pressing offers a range of bubble caps, including stainless steel, copper alloy, alloy steel, and MS (mild steel) bubble caps. These different materials cater to various distillation requirements. Contact Us