CNC Machining Parts Exporter

Can't Find What You're Looking For?

Get A Quote

Download

At Kuber Auto Pressings, we specialize in manufacturing and exporting high-quality CNC machining parts. With state-of-the-art facilities and a team of skilled professionals, we have the expertise to produce components that are precisely engineered to your specifications. Our extensive experience enables us to cater to diverse industries, including automotive, aerospace, electronics, telecommunications, and more

We prioritize quality at every stage of our manufacturing process. Our dedicated quality control team ensures that every CNC machining part undergoes rigorous inspection to meet the highest standards. By employing advanced measurement techniques and adhering to strict quality protocols, we maintain consistent quality throughout our product range. As an ISO certified company, we are committed to delivering excellence and reliability in every component we produce.

Equipped with advanced CNC machining technology, we can produce complex components with precision and efficiency. Our state-of-the-art machinery, including multi-axis CNC machines, allows us to achieve tight tolerances and intricate designs. Whether it’s milling, turning, drilling, or grinding, our CNC machining capabilities enable us to deliver components of superior accuracy and finish.

As a trusted exporter, we have a strong global presence and cater to clients worldwide. With a robust logistics network, we ensure timely and reliable delivery of our CNC machined components to various destinations. Our well-established export procedures and documentation expertise streamline the shipping process, ensuring a hassle-free experience for our customers.

What are CNC Machining Parts?

CNC machining parts refer to components or pieces that are manufactured using Computer Numerical Control (CNC) machining processes. CNC machining is a precise and automated manufacturing method that utilizes computer-controlled machines to remove material from a workpiece and shape it into the desired form.

In CNC machining, the design specifications of a part are first created using computer-aided design software. The CAD file is then converted into instructions that guide the CNC machine’s movements. These instructions specify the cutting paths, tooling requirements, and other machining parameters.

During the machining process, the CNC machine uses various cutting tools, such as drills, mills, lathes, or routers, to remove material from the workpiece according to the programmed instructions. This subtractive process allows for the creation of complex shapes, tight tolerances, and high-quality surface finishes.

CNC machining parts can be made from a wide range of materials, including metals such as aluminum, steel, titanium, or brass and composites. They are commonly used in various industries, including aerospace, automotive, electronics, medical, and manufacturing.

Types of CNC machining parts

Mechanical Components

Aerospace Components

Electronic Components

Medical Device Parts

Automotive Parts

Industrial Equipment Parts

Customized Parts

Key Features of CNC Machining Parts

High Precision

Complex Geometries

Consistency

Versatility

Efficiency

Quality Surface Finishes

Things to Consider When Selecting a CNC machining parts Exporter

1. Quality and Reliability

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

APPLICATION INDUSTRY - CNC Machining Parts Exporter

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

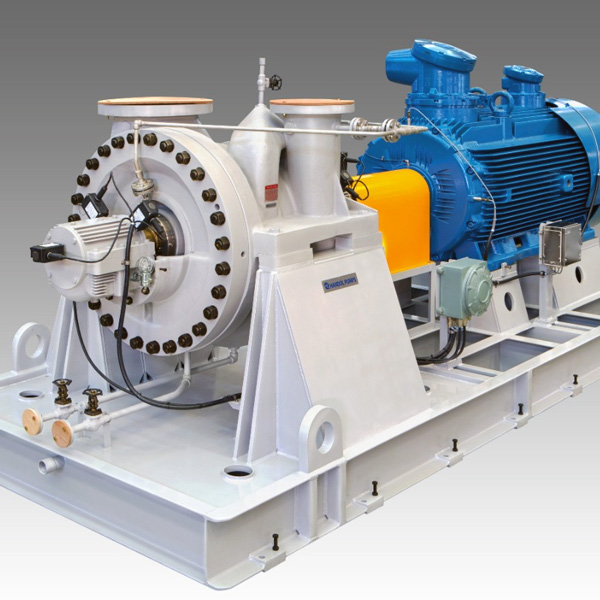

Motors

Pumps

Valves

Learn more about our Product Pipe Flaring and Swaging Manufacturer

Get In Touch

FAQ

We offer a high level of customization for CNC machined components. Our skilled team can work with your specific design requirements, tolerances, and finishes to deliver tailored solutions. Contact Us

To select a reliable CNC machining parts exporter, consider their experience, reputation, and customer reviews. Verify their quality control measures and expertise in producing the specific parts you require. Ensure they offer competitive pricing, timely delivery, and effective communication for a smooth export process.