Sheet Metal Components Manufacturer

Can’t Find What You’re Looking For?

Get A Quote

Download

Kuber Auto Pressing is a renowned manufacturer of sheet metal components, specializing in producing high-quality and precision-engineered parts for various industries. Sheet metal components are widely used in automotive, electronics, appliances, and other sectors due to their versatility, durability, and cost-effectiveness.

Kuber Auto Pressing utilizes advanced manufacturing techniques and state-of-the-art machinery to produce sheet metal components that meet industry standards and customer specifications. We emphasize precision engineering and attention to detail in their production processes to ensure that each component is of the highest quality.

Sheet metal components manufactured by Kuber Auto Pressing are fabricated from a range of materials, including stainless steel, aluminum, and carbon steel. The choice of material depends on the specific application requirements, such as strength, corrosion resistance, and weight considerations.

We offer a diverse range of sheet metal components, including but not limited to brackets, enclosures, chassis, panels, covers, and structural supports. These components are designed to fit seamlessly into various assemblies and systems, contributing to the overall functionality and performance of the end product.

What are sheet metal components?

Sheet metal components are parts that are made from thin sheets of metal, such as steel, aluminum, or iron. These components can be found in a wide range of industries and applications due to their versatility and durability. Sheet metal components are typically formed through a process called sheet metal fabrication, which involves cutting, bending, and shaping the material into the desired shape.

One of the key requirements for sheet metal components is strength. The thickness of the sheet metal used to make these components is measured in gauge, with lower numbers indicating thicker sheets. Thicker sheets provide greater strength and durability for the component. Another important requirement for sheet metal components is resistance to corrosion. Materials and coatings must be carefully chosen to ensure longevity for the component.

Types of Custom Sheet Metal Components

Enclosures and Cabinets

Brackets and Mounting Plates

Panels and Covers

Chassis and Frames

Heat Sinks and Cooling Components

Automotive Components

Precision Components

Precision components require high accuracy and tight tolerances to ensure quality and consistency during manufacturing processes. These components must meet strict specifications to function correctly within a larger system.

Precision components include gears, shafts, bearings, valves, nozzles among others which require precise measurements during production processes. These parts have critical functions within their respective systems; therefore any deviation from the required dimensions may cause failure leading to significant losses.

Advantages of Sheet metal components

Strength and durability

Lightweight

Versatility

Cost-effective

Electrical conductivity

Things to Consider When Selecting a Sheet Metal Component Manufacturer

1. Quality and Reliability

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

Sheet Metal Components - Material Of Construction

| Material | Stainless Steel 304, 304L, 316, 316L, 409L, 410 |

| Other | Copper, Aluminium, Copper, Brass, Inconel, Monel, Titanium, Duplex Steel etc. |

| Usage / Application | Industrial |

| Features | Rust resistance property, Dimensional accuracy, Easy installation |

Custom Sheet Metal Stamping For A Range of Materials

Cold Rolled Steel

Hot Rolled Steel

Stainless Steel

Aluminum

Galvanized

Beryllium Copper

Brass

Titanium

APPLICATION INDUSTRY - Sheet Metal Components Manufacturer

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

Motors

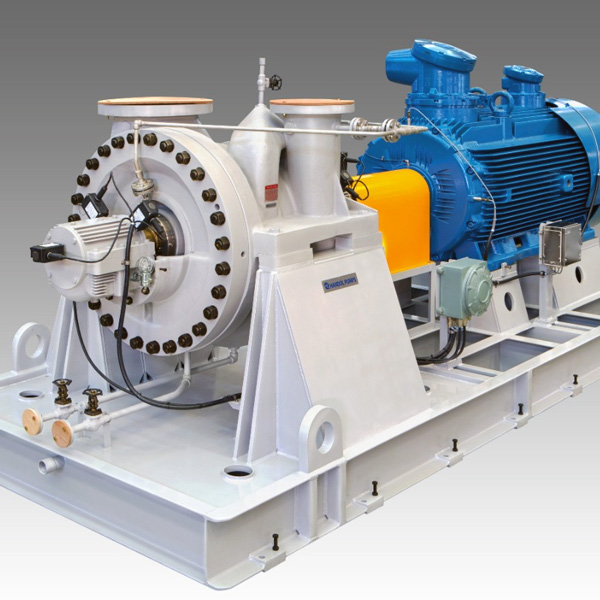

Pumps

Valves

Learn more about our Product Valve Components Manufacturer

Get In Touch

FAQ

Yes, sheet metal components can be easily customized to meet specific design requirements. They can be resized, reformed, or integrated with additional features or fasteners as needed. Customization allows for design adjustments, adaptations, or enhancements to cater to unique project needs. Contact Us