Valve Components: Find Your Ideal Manufacturer

When choosing a valve parts maker for ball valves, control valves, quarter-turn valves, and pipes, it’s essential to focus on quality, reputation, and product variety. Make sure they meet quality standards, have a good reputation, and offer a wide variety of products, fine surface finish, materials, and sizes. Check if they have experience in hand and use good quality forged steel materials. Look for makers with ISO certification. Choosing the right control valves, butterfly valves, pipes, and pneumatic actuators maker is vital for smooth operations. Follow these tips to find the right Valve Components Manufacturer

Introduction to Valve Components

Importance

Role in Various Industries

Factors to Consider When Selecting a Valve Components Manufacturer

Quality Standards

ISO 9001:2015 Certification

Material Quality

Reputation and Experience

Types of Valves Offered

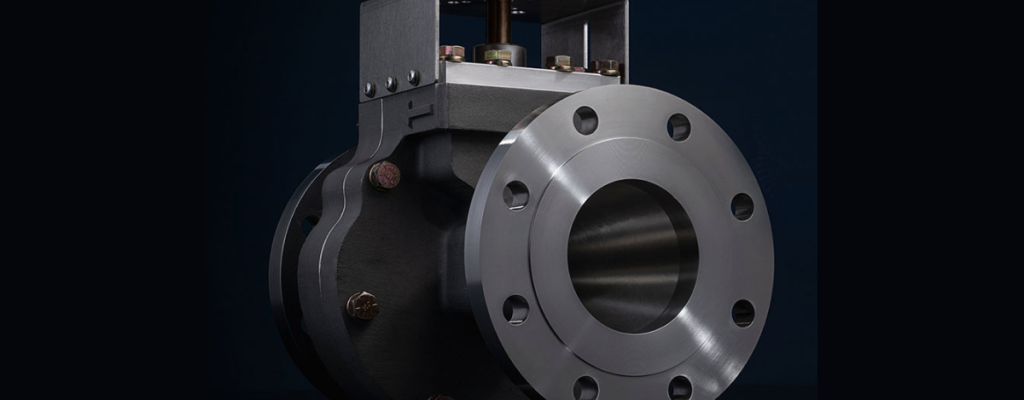

Various connection types:

1. Flange

2. Socket weld

3. Buttweld ends

It offers versatility:

1. Valve discs

2. Seats

3. Stems

4. bonnets

Ensure proper function and sealing. Actuators, valves, and glands play crucial roles in controlling and securing valve operations.

Manufacturing Capabilities

Technology and Machinery

Production Capacity

Considerations for Valve Manufacturers in India

When thinking about Indian manufacturers like Kuber Auto Pressing for valve components, it’s crucial to consider factors such as quality assurance, production capacity, and export capabilities. Kuber Auto Pressing stands out as a reliable choice, meeting all these requirements with ease. With a strong commitment to adhering to international quality standards and possessing the necessary certifications, Kuber Auto Pressing ensures peace of mind and confidence in the quality of its steel fittings.

Conclusion

When it comes to selecting the valve components manufacturer, Kuber Auto Pressing stands out as a reliable choice. With a strong emphasis on material quality and certifications. Kuber Auto Pressing ensures that its valve components meet the highest standards of performance and durability. Their reputation in the industry, coupled with their commitment to customer satisfaction. This makes them a preferred supplier for various sectors including oil and gas, construction, manufacturing, steel, pipe, fittings, and flanges. Choosing Kuber Auto Pressing ensures that you receive the best components tailored to your specific requirements, guaranteeing success and longevity in your applications.