Distillation is a fundamental process in chemical engineering, crucial for separating liquid mixtures based on their different boiling points. Within distillation columns, various components play vital roles, including bubble cap trays. In this guide, we delve into the significance of bubble cap trays in distillation columns, exploring their functionality, design, and the importance of selecting the right manufacturer.

Understanding Bubble Cap Trays

Construction and Design

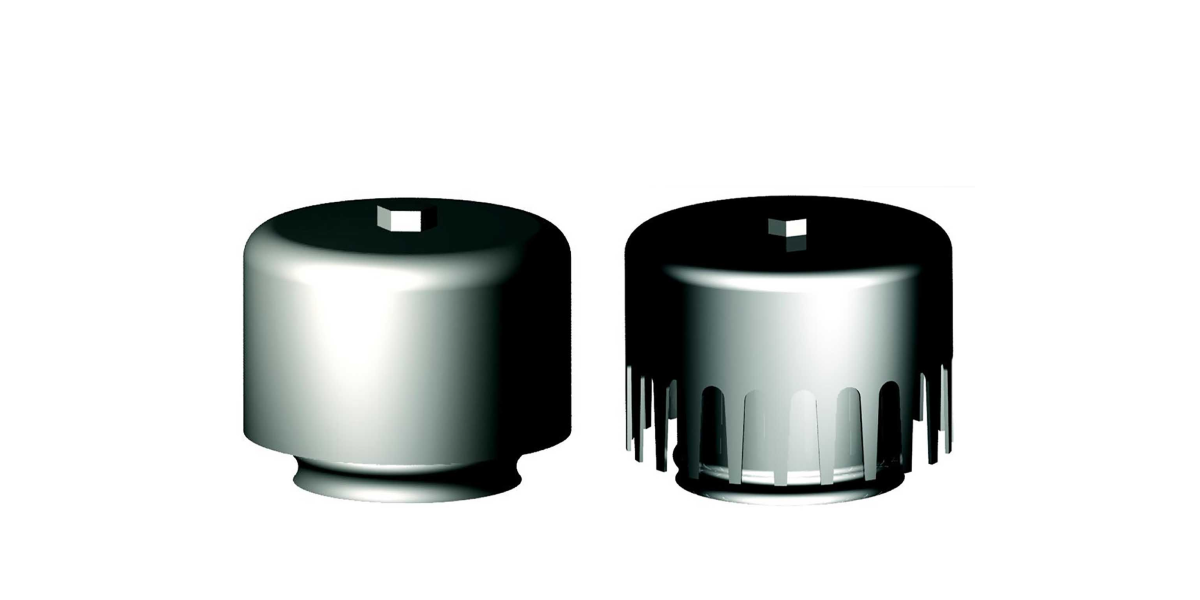

- Bubble cap trays consist of perforated plates with evenly spaced holes, each equipped with a bubble cap.

- The bubble caps are uniquely designed to allow vapor to pass through while trapping liquid underneath, creating a conducive environment for mass transfer.

- The trays are carefully engineered to provide optimal surface area for vapor-liquid interaction while maintaining structural integrity.

Operation and Mechanism

- As vapor ascends through the distillation column, it encounters the liquid on the bubble cap trays.

- Upon contact with the liquid, the vapor forms bubbles, which rise through the holes in the trays.

- The bubble caps serve to disperse the vapor evenly across the tray, ensuring uniform contact with the liquid phase.

- This intimate vapor-liquid interaction facilitates the transfer of components between phases, leading to effective separation based on differences in volatility.

Efficiency and Performance

- Bubble cap trays are known for their efficiency in promoting vapor-liquid contact, resulting in enhanced separation performance.

- The design of the trays optimizes surface area and residence time, maximizing the opportunity for mass transfer to occur.

- Proper vapor distribution and liquid sealing contribute to the overall effectiveness of the trays in achieving desired separation outcomes.

Applications and Versatility

- Bubble cap trays are versatile and adaptable to various distillation processes and applications.

- They can accommodate different feed compositions, operating conditions, and throughput rates, making them suitable for a wide range of industries.

- In petrochemical refineries, pharmaceutical production, and food and beverage processing, bubble cap trays offer reliable performance and consistent results.

Choosing the Right Bubble Cap Manufacturer

Expertise and Experience

Customization Options

Opt for manufacturers who offer customization options to tailor bubble cap trays to specific column designs and operating conditions. Customization may include adjusting tray dimensions, hole sizes, cap configurations, and material selection to optimize tray performance for your distillation process. A manufacturer that can accommodate custom designs and specifications will ensure that the bubble cap trays integrate seamlessly into your distillation system.